English

English

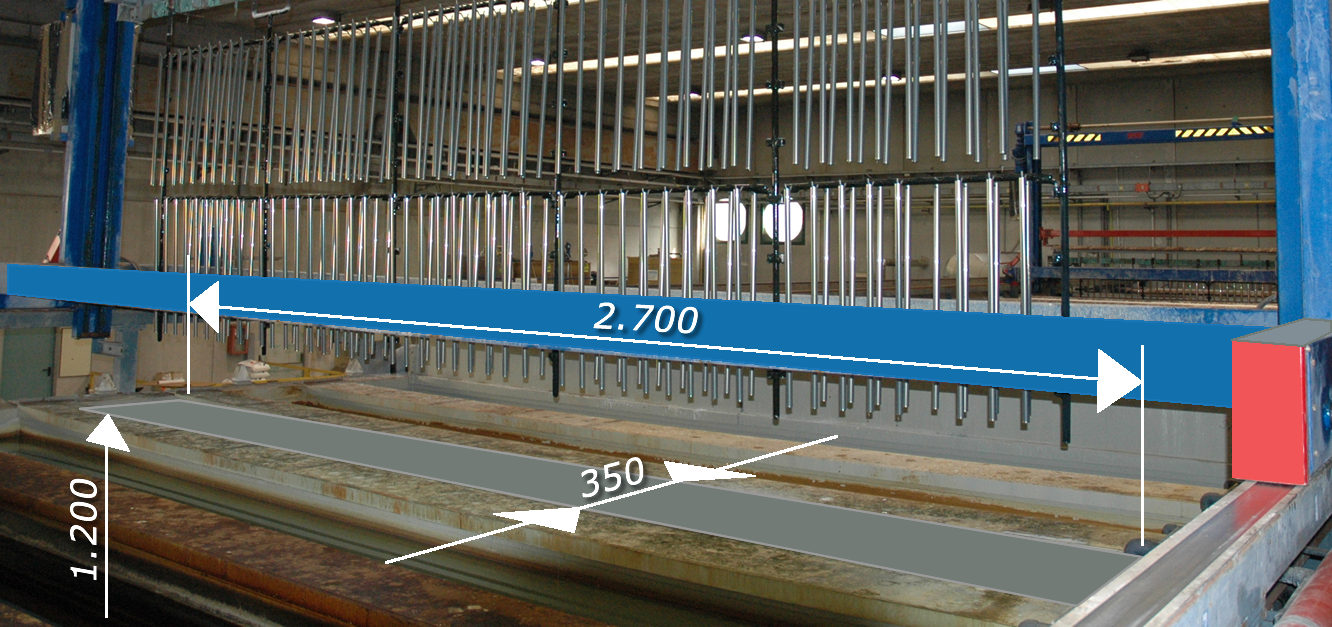

Production capacity

Production capacity of 700 ton/year for phosphatising.

Phosphating tubs dimension is 2.700 (length) x 350 (width) x 1.200 (height).

Protective layers

The very thin protective layers developed on the material to be protected are in the region of about ten microns. This thickness highlights a very small consumption of raw material and enhances the interest in these techniques in comparison to galvanising through immersion in molten pool even as far as energy consumption concerns. The material is first of all cleaned independently whether it must be galvanised or phosphatised.

Degreasing and pickling

This treatment is composed of two degreasing operations to remove any trace of grease of oil from the material surface. The first operation consists in a hot chemical washing (55°C) strengthened by handling and spraying of a degreasing solution; the second operation consists in an electrolytic washing at room temperature, carried out with the aid of rectified electrical current. The rust on the material is removed in a pickling solution of hydrochloric acid (5N).

Phosphatising process

Phosphatising is carried out by simple immersion in hot bath, with subsequent formation of protective iron and manganese phosphatic components.

The process mainly consists in immerging the already cleaned material into a hot phosphatic solution of manganese salts (85°-90°C), after activation in solution containing grain refining agent. After drying with warm air in oven, the material is impregnated with Castrol protective oil and then conditioned.